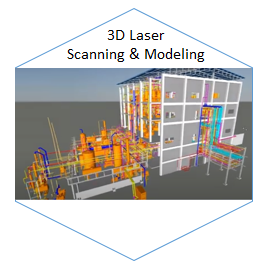

Laser scanning is becoming very popular to create 3D models. It can be used to create models of small objects as well as large facilities. 3D laser models are highly accurate and to the scale.

These are intelligent models and are perfect way for :

• Accurate documentation of brownfield plants (GA drawings and isometrics)

• Immersive field operators trainings

• Maintenance training

• Vendor trainings for issuing permit to work (PTW)

• Front end for 3D OTS systems

• Asset monitoring & maintenance programs.

Our Specialties:

1) Laser scanning of process plants

2) 3D modelling – dumb & intelligent models

3) Cross platform data integration

4) Data integration between Historian’s, Asset management systems, Maintenance systems & 3D models

Software Platforms:

1) Autodesk Plant3D

2) PDMS

3) SP3D – PDS

4) Cadworks

5) We are also specialized in cross platform conversion of models

Method to create models:

1. Laser scanning – Laser scanners are placed at different locations in the plant to generate sub-models.

2. Convert laser point cloud data to 3D primitives. This is also called as stitching sub-models into single model.

3. Convert to intelligent 3D models.

Applications of 3D laser scanning and modeling:

I. It helps to create accurate documentation of existing downfield plant, with exact dimensions, piping lengths, positioning of the equipments and its material take off.

II. The models prepared can be extensively used as an immersive technology for the training purpose.

III. It is an optimized and accurate method for maintenance of the plant and also for operators training as operator training simulator.

IV. These models are used for the vendor familiarization before issuing the permit to work (PTW) order.

Intelligent 3D models are used for BOM/MTO extraction, 2D drawing extraction (GA & Isometrics), and various other uses.